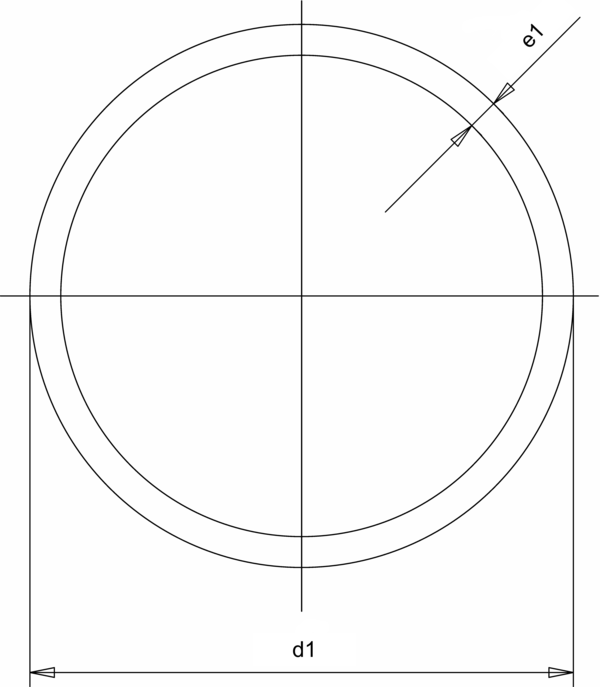

PE 100 Pressure pipes Pressure pipe

Order no. 010002848

High heat stability, UV-stabilised, creep strength at 50 years, 20°C, medium water = 10 Mpa

Product properties

- High chemical resistance

- Outstanding processing parameters

- High strength and rigidity

- Extremely versatile

Areas of use

- Port construction

- Civil engineering

- Pharmaceuticals and bioindustry

- Landfill engineering

- Mining

- Renewable energy

- Water supply

- Seawater desalination

- Elevated water tanks

- Sewage treatment plants

Approvals/certifications

- Produced from DIBt-approved moulding compound

- Drinking water certification as per KTW

- DIN 4102 B2 normal flammability (self-assessment without test certificate)

- Food compliance EU 10/2011

Processing

PE 100 schwarz Data sheet

High heat stability, UV-stabilised, creep strength at 50 years, 20°C, medium water = 10 Mpa

CaseStudy 63 - SIMONA® PE 100-RC Line Brochures

SIMONA® PE 100-RC Line pressure pipes to create an irrigation system pipeline using the ploughing method

PDF | 1.01 MB

CaseStudy 39 - SIMONA® SPC RC- and RC-Line Pressure Pipes – for Natural Gas Pipelines (HDD Method) Brochures

As part of a construction project for a new natural gas pipeline in the Swiss cantons of Solothurn and Bern, utility company SWG Grenchen required robust, pressureresistant plastic pipes. They had to be suitable both for trenchless and for sandbedless pipelaying. The choices made were SIMONA® SPC RC-Line Protective-Jacket Pipes and SIMONA® RC-Line Pressure Pipes.

PDF | 594.33 KB

CaseStudy 34 - Efficient biogas plant fitted with SIMONA® PE 100 Brochures

Operating throughout Europe, agriKomp GmbH is a company specialising in the development and manufacture of biogas plants. All the major components of the plants are manufactured in-house. Owing to their modular design, they can be added to at any time, providing a very high level of flexibility. The digestion process uses liquid manure, dung, green material, silage and cereal. The key components of the biogas plants have to be made of a material with maximum corrosion resistance. Therefore, agriKomp GmbH opted for SIMONA® PE 100. In contrast to steel, SIMONA® PE 100 pipes and fittings combine excellent corrosion resistance with a high level of UV stability, which makes them the perfect choice when it comes to the construction of high-end biogas plants.

PDF | 871.35 KB

CaseStudy 22 - "Beckton": SIMONA® PE 100 pressure pipes for UK’s first large-scale desalination plant Brochures

Climatic changes, population growth and an expected increase in consumption as a result of the 2012 Summer Olympic Games in Greater London are making it more and more important to develop drinking water resources in the UK. To this end a seawater desalination plant has been built in Beckton. The material and product of choice: corrosion-resistant SIMONA® PE 100 pipes. They were used to implement numerous customised engineering solutions over the entire period of construction.

PDF | 2.12 MB

CaseStudy 21 - Gel mixing systems made with SIMONA®PE 100 for the battery industry Brochures

KUSTAN GmbH & Co. KG, a specialist in industrial and environmental plant made of plastic, manufactures entire mixing units used in the production of sulphuric acid gel for the battery industry. For gel mixing systems operated by Chinese and Indian customers the choice of material, the structural properties and the selection of equipment had to be considered very carefully. Since the material for making the sulphuric acid storage tank and the gel mixing tank had to be extremely reliable, the company opted for PE 100.

PDF | 373.60 KB

CaseStudy 15 - Oversized biowashers made from SIMONA®PE-HWU sheets Brochures

In 2007 the Swiss company COLASIT AG manufactured three oversized biowashers designed for the purpose of cleaning exhaust air for cellulose manufacturer Sniace in northwest Spain, supplemented by an additional tower unit just a few months later. Each biowasher has a volume of approx. 767 m³, a height of 13.5 m and a diameter of 8.5 m. The total volume of the four biowashers is therefore approx. 3,000 m³.

PDF | 662.25 KB

work.info 01 - Heated element butt-welding Videos

Processing movie Heated element butt-welding acc. to DVS 2207-1

work.info 02 - Heated element socket welding Videos

Processing movie Heated element socket welding acc. to DVS 2207-11.

work.info 03 - Electrofusion welding Videos

Processing movie Electrofusion welding acc. to DVS 2207-1

work.info 4.1 - Heated element butt welding SPC-Pipe Videos

Processing movie Heated element butt welding SPC-Pipe acc. to DVS 2207-1

work.info 4.2 - Electrofusion socket welding SPC-Pipe Videos

Processing movie Electrofusion socket welding SPC-Pipe acc. to DVS 2207-1

work.info 05 - Non contact heated tool butt welding Videos

Processing movie non contact heated tool butt welding acc. to DVS 2207-6

work.info 06 - Simultaneous welding of double-containment Videos

Processing movie Simultaneous welding of double-containment pipe acc. to DVS 2207-1

work.info 07 - Cascade welding of double-containment pipe Videos

Processing movie cascade welding of double-containment pipe acc. to DVS 2207-1.